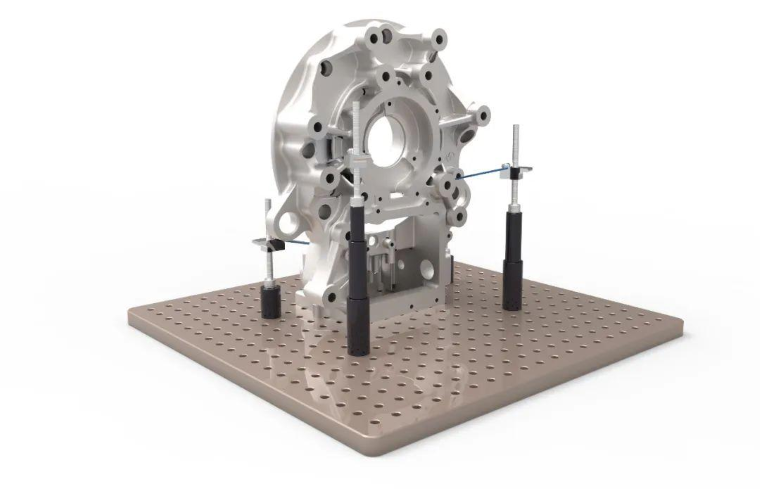

When machining workpieces on machine tools, in order to make the surface of the workpiece meet the technical requirements such as the size, geometric shape and relative position accuracy with other surfaces specified in the drawings, the workpiece must be clamped firmly before machining. The use of machine tool fixtures is conducive to ensuring the machining accuracy of the workpiece and stabilizing the product quality.

Before clamping the workpiece, the sand and mud in the workpiece must be removed to prevent the impurities from being embedded in the sliding surface of the slide plate, aggravating the wear of the guide rail or damaging the guide rail.

When clamping and correcting some workpieces with large size, complex shape and small clamping area, a wooden bed cover should be placed on the lathe bed under the workpiece in advance, and the workpiece should be supported by a pressure plate or a movable ejector to prevent it from falling and damaging the lathe. If the position of the workpiece is found to be incorrect or skewed, do not knock it hard to avoid affecting the accuracy of the lathe spindle. The clamp, pressure plate or ejector must be slightly loosened before making step-by-step corrections. When clamping the workpiece, pay attention to the position of the code and the extension length of the nut bolt on the pressure plate. In addition, the screws should not be pushed to the bottom when locking the corner. Copper Electrode is generally processed for locking plates. Before using the machine, the number of cuts should be compared with the number on the program sheet to ensure consistency. At the same time, check whether the plate screws are tightened. When coding, ensure that the coder will not be hurt by the knife. If necessary, communicate with the programmer. At the same time, if the bottom is squared, the coder must be aligned with the square pad position to achieve the purpose of force balance. Before using a vise to clamp, you must understand the tool processing depth to prevent the clamped position from being too long or too short.