When there are high precision requirements for the cross-section finish of stamped parts, and ordinary stamped parts cannot meet the high cross-section accuracy requirements, people have found a stamping method to control the cross-section accuracy, namely Fine Blanking. Simply put, fineblanking is stamping plus cold extrusion. Under the premise of equivalent quality, fine blanking is a low-cost alternative to machining, powder metallurgy and other processes due to its high processing efficiency.

Ordinary stamping can process almost any material, as long as the mold steel is strong enough and the press pressure is sufficient. However, materials used for fine blanking need to have good plasticity, low yield ratio and high elongation in order to effectively transmit compressive stress between material crystals to suppress cracks; they need to have good organizational structure, if the material structure is not stable,it is difficult to produce uniform inhibition under constant pressure conditions. Usually the tensile strength needs to be below 600MPa~700MPa, and generally the material structure that is too hard is relatively coarse (such as martensite).

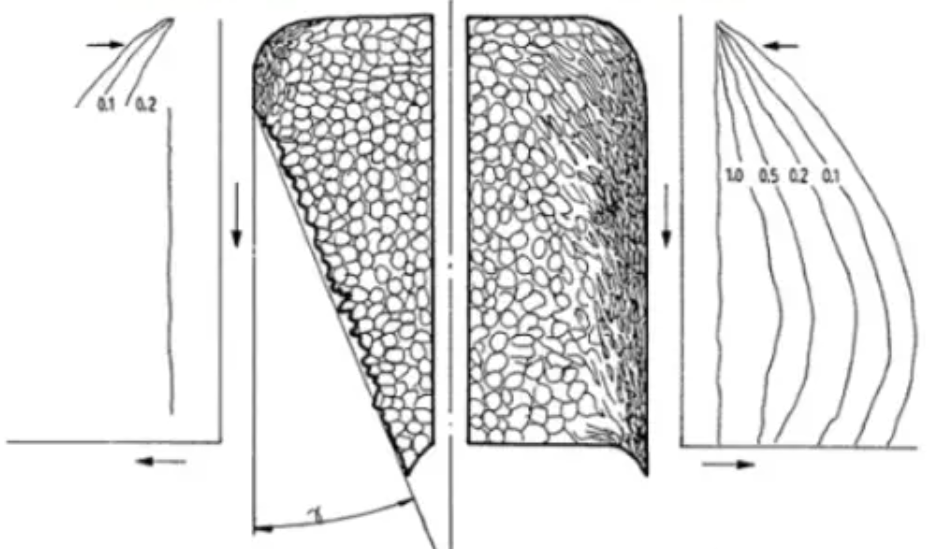

The essential difference between the fine blanking process and the general punching process is that ordinary stamping cannot effectively avoid the tearing of the cross section during blanking, while fine blanking tries its best to suppress the tearing of the sheet during blanking. Ordinary stamping equipment generally provides one-way power (there are also dual-power presses for processing special-shaped products), that is, punching force. The table tops also vary greatly. For example, the length of the 800T press table ranges from about 2m to about 5m. The fine blanking machine can provide three powers: blanking force, blank holder force, and anti-ejector force. Moreover, the fineblanking equipment has a compact structure and a small table. The length of the table of a fineblanking machine of about 800T is generally about 1m. Of course, like ordinary stamping machines, fine blanking machines also require other supporting auxiliary equipment. Generally, the necessary auxiliary systems of fine blanking machines include uncoiling and leveling feeders, mold lubrication systems and parts waste separation systems.