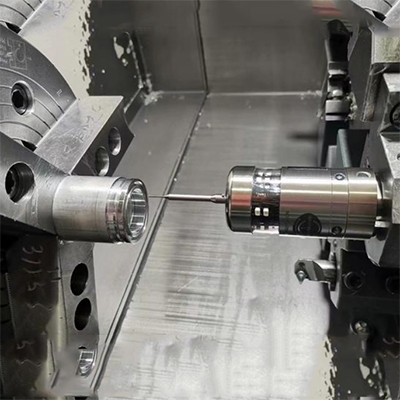

Has good experience and high-precision equipment to manufacture various precision parts according to customer requirements

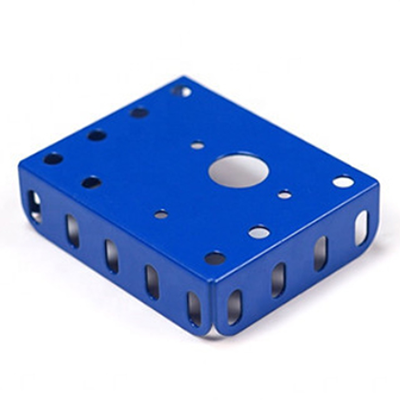

Can process various types of materials, 316, 304 stainless steel, carbon steel, alloy steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, plastic, acrylic, POM and other raw materials, can be processed into square, round combination of complex structure parts.

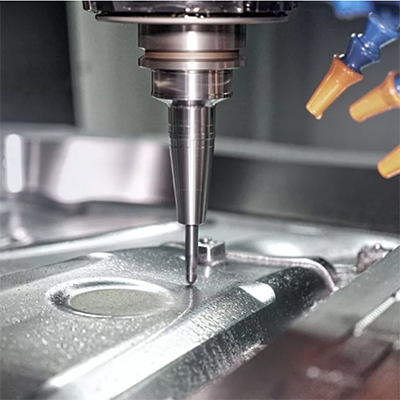

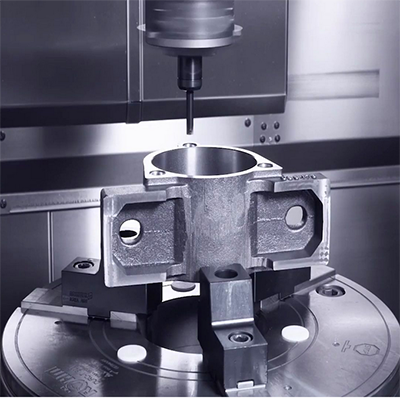

5 axis CNC machining technology is a kind of numerical control machining technology, which is based on the three-axis linear motion (X, Y, Z axis), and increases the movement of two rotating axes (A, B axis). This processing technology can complete the processing of multiple directions on a single workbench, so as to achieve high efficiency and high precision processing effects. 5 axis CNC machining technology is widely used in aviation, automotive, mold, medical equipment and other fields.

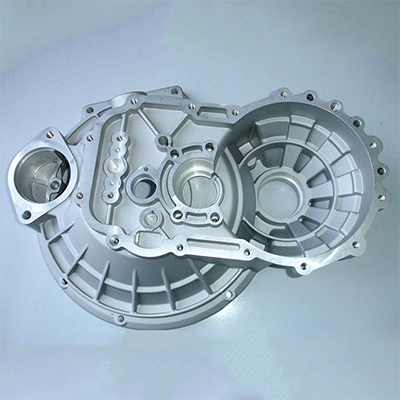

Aluminum alloy die casting process is an efficient and precise casting process, by injecting high temperature and high pressure liquid metal into the casting mold, quickly cooling and forming aluminum alloy parts with good mechanical properties and surface quality.

Metal stamping is processing that use punches and molds to let stainless steel, iron, aluminum, copper and other plates materials to deform or fracture, to achieve a certain shape and size of a process.

The main processes are cutting, bending edge, bending forming, welding, riveting, etc. Sheet metal parts can be processed by stamping, bending, stretching and other means